Unlimited Possibilities

Cummings Aerospace’s unparalleled experience in engineering, manufacturing, and program management ensures on-time, exceptional product and service delivery. From requirements development to hardware delivery, we provide solutions in all phases of product realization. Our execution approach uses proven program management processes to achieve our customers’ goals, no matter how complex.

System Design & Analysis

Our systems engineering processes support requirements specification development to ensure system design meets customer expectations. Model-based tools develop and refine test requirements, test plans, and readiness reviews. Iterative hardware design engineering uses digital modeling and simulation, agile test methods, and prototype development. Specifications development is intercalated with each design level, becoming more intricate as the system architecture evolves. Integrated engineering, manufacturing, and quality processes guarantee that our hardware solutions fulfill customer requirements.

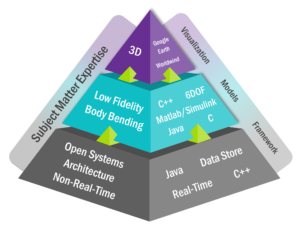

Modeling & Simulation

Cummings Aerospace engineers are skilled in the modeling and simulation (M&S) of aerospace vehicles used at all levels of the design hierarchy—from providing data to make campaign level decisions to detailed subsystem trade studies. Built from scratch, our models have been used as the basis for designing and building flight-vehicles, radars, satellites, and communications systems. We maintain an extensive model library of threats, interceptors, sensors, communications, and battle management, aerodynamics, propulsion, actuation systems, RF/IR propagation, environmental effects, and orbital mechanics.

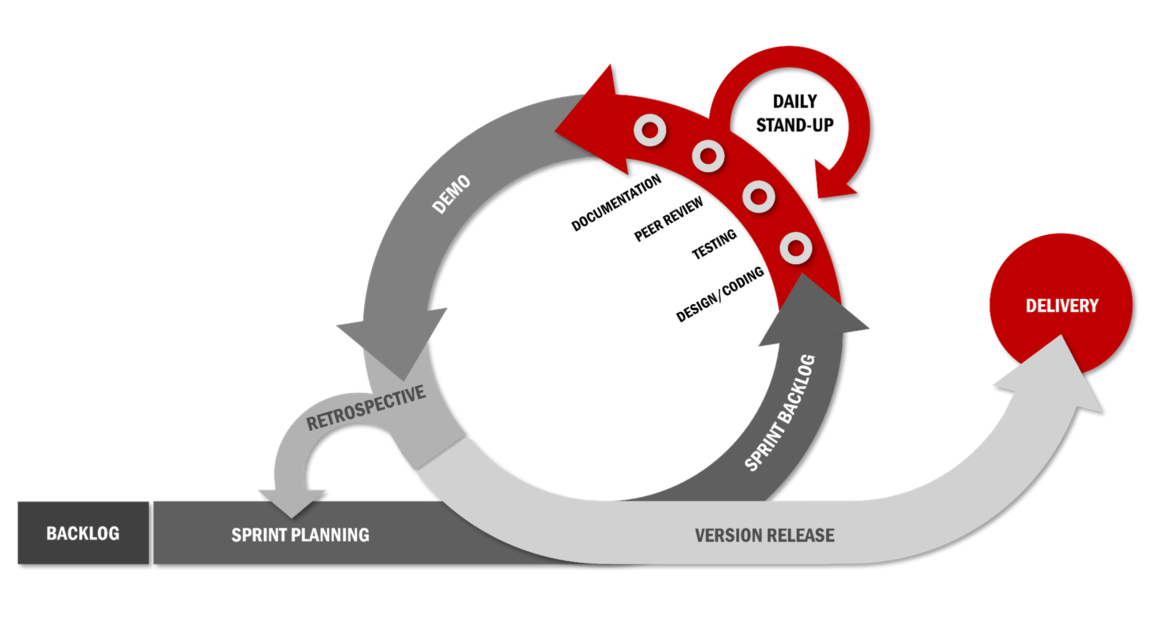

Software Development

Cummings Aerospace applies an agile Scrum methodology that is guided by industry-standard practices. Our processes include uncompromising testing and verification, utilizing peer reviews, automated testing tools, and rigorous metrics tracking. The flexibility of the iterative, incremental agile scrum software development approach allows us to quickly respond to changes in requirements or budgets.

Manufacturing

Our manufacturing facility in Huntsville, Alabama includes a precision machine shop with modern CNC machining, electronics integration with soldering and RF component testing, and IPC-620-certified cable manufacturing. Traditional and advanced manufacturing equipment comprises both 3-axis machining and polymer-based 3D printing. CNC machining uses the models and assemblies created in CAD/CAM software to turn designs into prototypes, finished products, and production runs. Our electronics design and fabrication team performs expert technical data package development, custom components design, and construction of custom wire harnesses.

Systems Integration & Test

Cummings Aerospace leverages a model-based methodology to develop test plans and documentation, execute ground and flight test events, and conduct post-test analysis. In addition to determination of assembly and integration processes, our engineers and technicians assess manufacturing methods, materials, and integration processes. Lab testing and prototype production supports full-analysis integration and early identification of potential problems.